Top Fruit Exports and How to Avoid Cargo Claims: Oranges

5 Common Causes of Shipping Delays and Impact on Cargo Claims

August 25, 2023

Vital Documents for Expedited Cargo Claims Resolution

September 1, 2023Oranges are not only a popular and nutritious fruit, but they are also a significant commodity in international trade. Global sales for orange exports reached an impressive US$4.7 billion in 2022. When it comes to shipping oranges, maintaining their quality during transit is crucial to avoid cargo claims and ensure customer satisfaction.

Cooling and Storage: Ensuring Freshness

Citrus packinghouses often overlook the essential stage of rapid cooling. Rapid cooling reduces respiration, slows the growth of pathogens, minimizes water loss, and extends the shelf life of oranges. Oranges are commonly subjected to room-cooling or forced-air cooling methods. To ensure successful cooling, it’s imperative to maintain robust airflow through the cartons. The carton design should include a minimum of 5% side venting to facilitate consistent airflow throughout the entire cargo load.

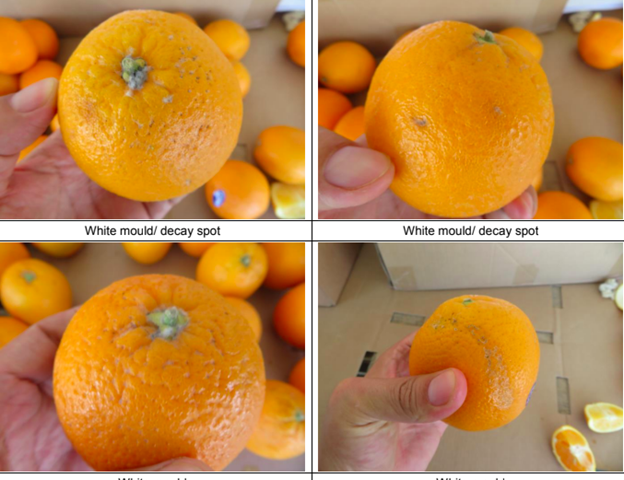

Oranges fare better when left on the tree during typical weather conditions. Avoid cold storage if the fruit’s storage potential has been used up due to extended tree storage. Pre-cool the fruit to reduce respiration and apply an approved fungicide before storage. Regular inspections are crucial during storage to detect decay or issues promptly. Oranges can be stored for up to 12 weeks under ideal conditions.

Preventing Chilling Injury:

Chilling injury, caused by rapid temperature changes, can result in pitting, brown staining, increased decay, and off-flavors. Symptoms may appear after moving the fruit to room temperature following cold storage. Preventing chilling injury involves temperature conditioning before storage, using high CO2 atmospheres, intermittent warming, and the application of certain fungicides. Storing fruit at non-chilling temperatures is the best way to avoid this issue.

Transit Temperature and Packaging:

The optimal temperature for exporting oranges varies depending on the cultivar and origin. For instance, Navel oranges from Moroccan and Spanish sources are best transported at temperatures between 2°C to 3°C, while Salustiana oranges from Spain require a temperature of 2°C. Valencia Late oranges, whether from Moroccan, Cypriot, or Spanish origins, maintain quality between 2°C to 3°C, with South African ones at 4.5°C, and USA (California) ones at 2°C to 7°C.

When shipping in warm conditions, it’s advisable to include a dry-ice pack at the box’s base. To ensure their safe journey, individually wrap each fruit with brown packaging paper or tissue paper before placing them in a sturdy cardboard box. For added protection, line the box with bubble wrap, air packs, plastic peanuts, or packaging foam. Prevent bruising by securing each fruit with bubble wrap or foam padding, taking care to avoid direct contact between plastic and the fruit to prevent sweating during transit.

Mixed Loads and Cautions:

Oranges should not be shipped with products that emit ethylene, as this gas can accelerate decay. Additionally, low oxygen levels can delay senescence, while elevated CO2 levels might reduce chilling injury symptoms in certain cases.

Exporting oranges successfully requires meticulous attention to cooling, storage, and transportation conditions. For businesses facing the challenges of cargo claims, Recoupex offers expertise in cargo claim recovery. By adhering to best practices, exporters can ensure that their oranges arrive at their destination markets with optimal quality, reducing the risk of cargo claims.

Recoupex is a hub of transport lawyers – experts in cargo claims. We assess your case quickly. We have successfully recovered claims from Maersk, Sealand, Hapag-Lloyd, Mediterranean Shipping Company – MSC, CMA CGM, and other carriers.