5 Challenges transporting bananas and how to fix them?

Fatal mistakes that kill cargo survey report

August 12, 2020

Would you do THIS for money? Cargo insurance deductibles revealed

September 9, 2020When to transport a banana?

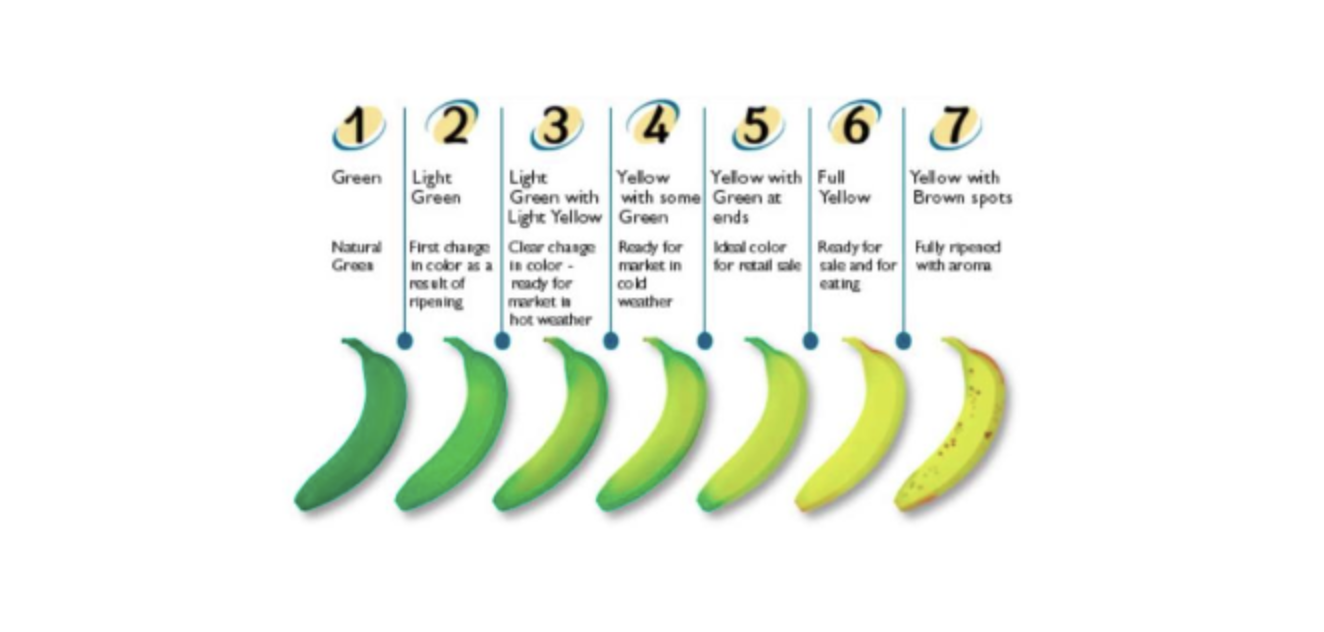

As all banana experts know, the banana undergoes three developmental stages:

- The Green Life Stage

- The Climacteric Stage

- The Ripening Stage

Transportation of the banana should take place during the climacteric stage so that ripening can be done at destination prior to sale.

Things to remember prior to packaging

- Load fruit into refrigerated space without delay.

- Cooling process must be as rapid as possible after harvesting.

- Avoid ethylene accumulation in the atmosphere surrounding the bananas.

Bananas should ideally ship at the 2 ½ to 3 stage according to the guide below.

5 Pitfalls during transportation

Let’s be honest… we are not all banana experts! We cannot expect a Formula 1 driver to be MasterChef, so why would we expect a transporter to understand the stages of banana ripening? It is up to the exporter /shipper to ensure transporters are properly informed of the cargo and cargo requirements they are carrying. The most popular reasons why a banana spoils during transportation are:

Improper Packaging:

Packaging of the green fruit assists to control the Oxygen (O₂) and Carbon Dioxide(CO₂) effects on the fruit, thus extending the climacteric stage of the banana, allowing for longer storage period.

Temperature Control (too high):

This will allow a banana to ripen too quickly and rot.

Temperature Control (too low):

This will cause the banana “chilling injury” (causing skin discoloration,insipid taste and failure to ripen).

Humidity Control:

Oxygen (O₂) below 2% may cause dull yellow or brown skin discoloration, failure to ripen properly, and off – flavors. Carbon dioxide (CO₂) greater than 5% may cause the fruit to soften while still green and confer undesirable texture and flavor.

Long Transit Time:

The storage life of a banana is 4 weeks, a long transit time may cause ripening, and possible rotting, to occur during transportation.

Let’s fix problems

Container of bananas is worth of 12 000 to 15 000 USD, not to mention loss of profit ! Let’s take measures to ensure cargo is delivered in the best possible condition.

- Ensure packaging regulations are strictly followed. For guidelines click Here.

- Ensure correct temperature limits are manifested correctly on the Bill of Lading (BL).

- Ensure fruit is delivered for loading within plus-minus 2 degrees of the temperature required for safe transportation.

- The carrier/shipping line has the right to refuse cargo not delivered within these limits. Often they accept this cargo for transportation and use “hot stuff” argument to reject in full your claim for damage.

It is the responsibility of the shipper to set and/or check the temperature of the container at time of loading. Do not load fruit into a container until the container has reached the desired temperature and holding stable.

- It is also the shipper’s responsibility to set and/or adjust vents in order to control humidity level. Ensure required humidity level is reached and stable prior to loading fruit into a container.

- When booking, consider choosing a less popular route. This could reduce the chances of your cargo getting rolled from vessel to vessel.

Your freight forwarder or booking agent can advise about more reliable cargo routing as some ports are extremely congested at certain times of year.

Other than that You are all set and good to Go Bananas!