Recovering Loss from Cargo Spoilage in Extreme Heat and Vessel Delays

Lost Cargo Containers at Sea: How to Prove, Process Claims, and Mitigate Losses

June 9, 2023

Can Ocean Carrier Charge Demurrage Fees to Shippers Indefinitely?

June 16, 2023As the scorching summer heat sweeps across Asia sometimes reaching staggering temperatures of up to 50 degrees Celsius, exporters face a daunting challenge: the spoilage of cargo, particularly fresh produce, and foodstuff. The combination of intense heat and delays in vessel schedules has led to thousands of cargo claims submitted by exporters to ocean carriers.

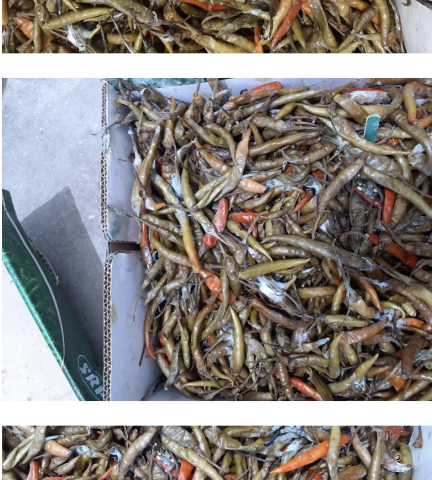

spoiled chilies due to extreme heat and vessel delays

In this article, we will explore the various precautionary measures exporters can take to mitigate cargo spoilage and discuss strategies to recover losses when preventive measures fall short.

- Understanding the Impact of Extreme Heat on Cargo:

Before diving into recovery strategies, it’s essential to comprehend how extreme heat affects different types of cargo. High temperatures can accelerate the deterioration of perishable goods, causing spoilage, loss of freshness, and reduced shelf life. Understanding the vulnerabilities of your specific cargo enables you to tailor your mitigation efforts accordingly.

- Implementing Effective Precautionary Measures:

While preventing cargo spoilage entirely may be challenging in extreme conditions, implementing a range of precautionary measures can significantly reduce the risk. These measures may include:

- Proper Packaging and Insulation: Optimal packaging and insulation are crucial to shield cargo from excessive heat. Utilize insulation materials, refrigerated containers, or thermal blankets to maintain the desired temperature throughout the journey.

- Temperature Monitoring Systems: Install temperature monitoring systems to track the cargo’s conditions in real-time. This allows exporters to identify potential issues early and take corrective actions promptly.

- Efficient Loading and Unloading Processes: Minimize exposure to extreme temperatures during loading and unloading by streamlining these processes. Ensure that cargo remains in temperature-controlled environments as early as possible after the harvest.

- Recovering Losses from Spoiled Cargo:

Despite taking precautionary measures, cargo spoilage can still occur. When faced with losses, exporters can explore the following avenues for recovery:

- Documentation and Evidence: Maintain detailed documentation and evidence to support your claim. This may include temperature records, photographs of damaged cargo, invoices, and any relevant communication with shipping and logistics partners.

- Engaging Legal and Recovery Services: In cases when carriers reject claim seeking for the legal and recovery help may be necessary. These professionals specialize in assisting exporters in recovering losses through legal means negotiating settlements.

Exporters operating in regions with extreme summer heat face a constant battle against cargo spoilage, which can result in substantial financial losses. By implementing effective precautionary measures and understanding the recovery options available, exporters can mitigate risks and seek compensation. Remember, proper planning, proactive measures, and timely action are key to overcoming the challenges posed by vessel delays, container roil overs in the hot climate countries.

Recoupex is a hub of transport lawyers – experts in cargo claims. We assess your case quickly. We have successfully recovered claims from Maersk, Sealand, Hapag-Lloyd, Mediterranean Shipping Company – MSC, CMA CGM, and other carriers.