4 ways to ensure cargo is not loaded in a crappy container. Container seaworthiness revealed.

Why do I need a destruction certificate for my cargo claim?

December 13, 2020

How to stuff cargo like a Pro?

February 4, 2021Way too often shippers are forced to absorb losses when cargo is damaged in transit due to BAD container condition. I have found the 4 reasons how to ensure you do not bear responsibility for loading cargo in a crappy box and I’ll show you why.

What is Seaworthiness?

When exporting cargo in a carrier owned container (COC), shippers rely on carriers or shipping lines to provide a seaworthy container which is suitable and reasonably fit to carry cargo safely for the intended voyage. In other words, a vessel, AND all the equipment supplied for use by vessel owner must be in seaworthy condition at the beginning of a voyage.

Shippers’ Responsibility

Although it is the responsibility of the carrier to supply a seaworthy container to shippers, responsibility also falls to shippers to inspect the container prior to loading of cargo to ensure that the container is fit for its intended use (Remember BL clause load, stow, count ?)

Once an unseaworthy container is accepted and packed by a cargo interest, and, for example, there has been water ingress to the container during the sea voyage, carriers will reject claims on the basis that the shipper accepted the container as fit for use.

How to Check Seaworthiness?

As it is the cargo interest’s duty to also check and approve the container before stuffing, it is important for them to carry out a few checks before commencing loading operations:

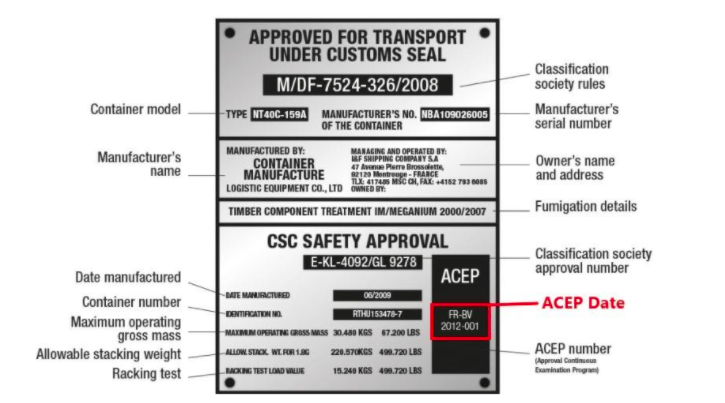

The CSC Plate – ACEP Date

Check the CSC plate for the last inspection date. All containers should undergo regular checks and be maintained if necessary. According to Bureau International des Containers (BIC):

“containers operated under ACEP must be properly and regularly inspected as part of their regular operation and at a very minimum, within the intervals required by PES (period examination scheme). Containers operated under the ACEP scheme must display the scheme number on the CSC plate; this is often in the form of a decal.”

ACEP requires containers to be maintained periodically under PES (periodic examination scheme); the first inspection should be carried out 5 years from the date of manufacture of the container, thereafter the container should be carried out once every 30 months.

So, if you notice that the last ACEP inspection date is more than 5 years prior, it is safe to assume that the container is not considered seaworthy, according to BIC.

Rust

Following the ACEP date check, take a walk around the container, and if possible, take a look at the roof of the container. Look for rust! Rust is a container’s (and your cargo’s) worst enemy. Through major rusty areas, tiny pinholes may develop during a sea voyage, causing water ingress to the container and damage to cargo. Reject a container with major rusty areas as you never know when pin holes may develop!

The Light Test

This is of significant importance to carry out for every container you are about to stuff. It is a very quick and simple way to test whether the container you are about to stow your cargo into is watertight.

Enter the container and ask someone outside to close the doors. Take a walk around the entire container looking at the roof, side panels, floor boards and around the doors. If you see any light infiltrating the container, then you will know that the container is not watertight. Reject the container and request a new one!

It is important to carry out the light test when the container is not in a stack, but freestanding. If the container is in a stack, you will not be able to conduct the test with conclusive results as the other containers in the stack will block any possible light infiltration.

Door Gaskets

Once the light test has been completed, step out of the container and look at the doors. Check the rubbers around the doors are not worn, torn and are sealing around the container tightly. Often rust build up around the doors cause the gaskets to no longer fit snugly. If you find any defects to the door gaskets or major rust build up where the gaskets meet the container, immediately reject the container and request a replacement.

Above: Damaged door gasket

Conclusion

The following are some take-away pointers when considering whether the container supplied to you is seaworthy:

Ensure the ACEP date on the CSC plate is not more than 5 years old.

Ensure the container is not too rusty.

Conduct a thorough light test while the container is freestanding.

Ensure door gaskets fit snugly to the container when the doors are closed.

The most important thing to remember is that you HAVE THE RIGHT to reject a container and request a replacement. The best practices involve to train you driver to check above before picking up container from the CY.

To avoid cargo damage and disputes later never accept a sub-grade container!